| Sign In | Join Free | My uabig.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My uabig.com |

|

Brand Name : Debon

Model Number : DB-TCM

Certification : SGS, ISO9001

Place of Origin : CHINA

MOQ : 1

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000 pcs per month

Delivery Time : 7-30 working days

Packaging Details : Crate or Pallet

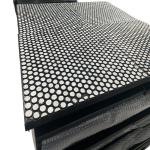

Name : Ceramic Wear Tiles

Material : High Alumina Ceramic, Zta cearmic, HPA ceramic

Fastening : Bolt on, Magnetic, CN bonding layer, etc.

Ceramic Shape : Cylinder, Hexagonal tiles, Rectangular, Square,special shape

AI2O3 : 92%; 95%; 99% alumina ceramic

Usage : Wear-resistant liners; Manufacturing processing; Ballistic protection;Medical implants; Aerospace components; Electronic components

Processing Service : Bending, Welding, Cutting, Punching, Moulding

Advantage : Factory price,high quality,long service life

HS Code : 6909120000

Wear Components Alumina Ceramic Tiles For High Wear Applications

Ceramic Wear Tiles Description:

Ceramic wear tiles are specialized ceramic materials that are designed to protect surfaces subjected to abrasive and erosive wear. They are typically made from high-strength ceramic materials, which are engineered to resist wear and tear.

Ceramic wear liner is a type of protective lining used in industrial applications to protect equipment and surfaces from abrasive or corrosive materials. The liner is typically made of high-quality ceramics, such as alumina, zirconia, or silicon carbide, that offer excellent resistance to wear, impact, and high temperatures.

Ceramic Wear Tiles Specification:

| Specification (mm) | Thickness of ceramic (mm) | Thickness of rubber (mm) | Thickness of steel backing plate | Total thickness (mm) |

| 300x300x36 | Φ21x21 | 9 | 6 | 36 |

| 300x300x50 | Φ31x31 | 13 | 6 | 50 |

| 250x250x36 | Φ21x21 | 9 | 6 | 36 |

| 250x250x50 | Φ31x31 | 13 | 6 | 50 |

| 250x250x18(17.5x17.5x8) | 7 | 5 | 6 | 18 |

Ceramic Wear Tiles Features:

Ceramic Wear Tiles Application:

We offers a wide range of conveyor wear liner plate composed of rubber and ceramic blocks and cn bonding layer or steel backing plate to provide superior impact resistance and abrasion in hard rock mining and other bulk materials handling applications. The range depends on the different abrasion, impact and material flow needs unique to individual industries and operations.

Ceramic Wear Tiles Package:

Standard export packing, plywood pallet, no wood, no need fumigation

Pallet size: 1000*1000*620mm, Pallet weight: 1.2 tons

Pallet quantity for each 20GP container: 20~24 pallets

Why choose us:

1. Rich experience on production process of Rubber ceramic lining plate

2. Strict quality control on rubber ceramic wear liner

3. Good delivery time

4. Custom shape rubber ceramic lining plate are available.

5. Excellent bonding between rubber and ceramic

We are a factory dedicated to producing ceramic wear liner and have been improving the properties of ceramics. We use high quality rubber to offer better impact resistance and high quality rubber can also help holding the ceramic tiles, no ceramic tiles falling.

|

Abrasion Resistant High Alumina Ceramic Tiles 300x300 Conveyor Chute Liners Images |

Rectangular Hex High Alumina Ceramic Tiles Ceramic Rubber Composite Liner

Rectangular Hex High Alumina Ceramic Tiles Ceramic Rubber Composite Liner

Ceramic Chute Lining Alumina Ceramic Lining For Conveyor

Ceramic Chute Lining Alumina Ceramic Lining For Conveyor

Impact Resistant Ceramic Wear Tiles Cylinder Hexagonal Ceramic Rubber Composite

Impact Resistant Ceramic Wear Tiles Cylinder Hexagonal Ceramic Rubber Composite

Ceramic Embedded Rubber Liner Custom Size Magnetic Wear Liners

Ceramic Embedded Rubber Liner Custom Size Magnetic Wear Liners

CN Bonding Ceramic Wear Tiles Alumina Ceramic Lining Panel For Mining

CN Bonding Ceramic Wear Tiles Alumina Ceramic Lining Panel For Mining

Wear Resistant Ceramic Wear Tiles 92% 95% Alumina Ceramic Liner Pipe Linings

Wear Resistant Ceramic Wear Tiles 92% 95% Alumina Ceramic Liner Pipe Linings

High Alumina Ceramic Wear Tiles Mining Chutes Industrial Ceramic Linings

High Alumina Ceramic Wear Tiles Mining Chutes Industrial Ceramic Linings

99% Alumina Ceramic Wear Resistant Lining Zta Ceramic Wear Plate

99% Alumina Ceramic Wear Resistant Lining Zta Ceramic Wear Plate

99% AI2O3 Ceramic Wear Tiles ZTA Toughened Zirconia Ceramic Tiles

99% AI2O3 Ceramic Wear Tiles ZTA Toughened Zirconia Ceramic Tiles